Discover the brands and technologies from our business units Henkel Adhesive Technologies and Henkel Consumer Brands.

Saving energy in production

Emissions of gases like carbon dioxide (CO2) are changing our planet’s climate and creating one of the most urgent challenges humankind has ever faced. These emissions are generated when fossil fuels are burned to create energy. Companies can contribute to tackling climate change by switching to renewable energy – and also by improving efficiency in their production processes. Here are three examples from three different continents that show how we’re cutting energy consumption at our factories worldwide.

Climate change is a crisis with potentially dramatic consequences for everybody on Earth. That’s why individuals and organizations around the globe must take decisive action to tackle it immediately. In this spirit, the United Nations has set a clear target for limiting the rise in our planet’s temperature as part of the Paris Agreement on Climate Change. At Henkel, we’re bringing this to life by striving to become a climate-positive company by 2040. Our efforts to achieve this cover the entire value chain and begin with our own production sites, where we aim to cut our CO2 footprint by 65 percent by 2025 and 75 percent by 2030 (base year 2010). We’re taking steps to cut energy consumption at all of our sites worldwide, including designing sustainable factories, making our processes more efficient, switching to renewable energy, and much, much more.

Energy-efficient design as the starting point in Kurkumbh, India

Our approach to increasing energy efficiency at our production sites begins when we design new factories. For example, our factory in Kurkumbh, India, was designed to have the smallest possible impact on the environment while meeting the highest standards for sustainability. The site layout was developed in line with lean manufacturing concepts that organize material flows in the best possible way to increase productivity, minimize waste and cut emissions. Alongside highly efficient equipment, it uses digital technology to optimize processes, and features smart systems for ventilation, air conditioning and lighting. On top of this, the roof is covered by 7,000 square meters of solar panels that generate more than 1,000,000 kilowatt hours of energy and save around 800 tons of CO2 each year – and plans are in place to add more panels soon and to purchase additional solar power from an external provider. In recognition of its energy-efficient design, the factory is one of only a handful of chemical manufacturing sites in the world that have received the LEED Gold certificate from the US Green Building Council.

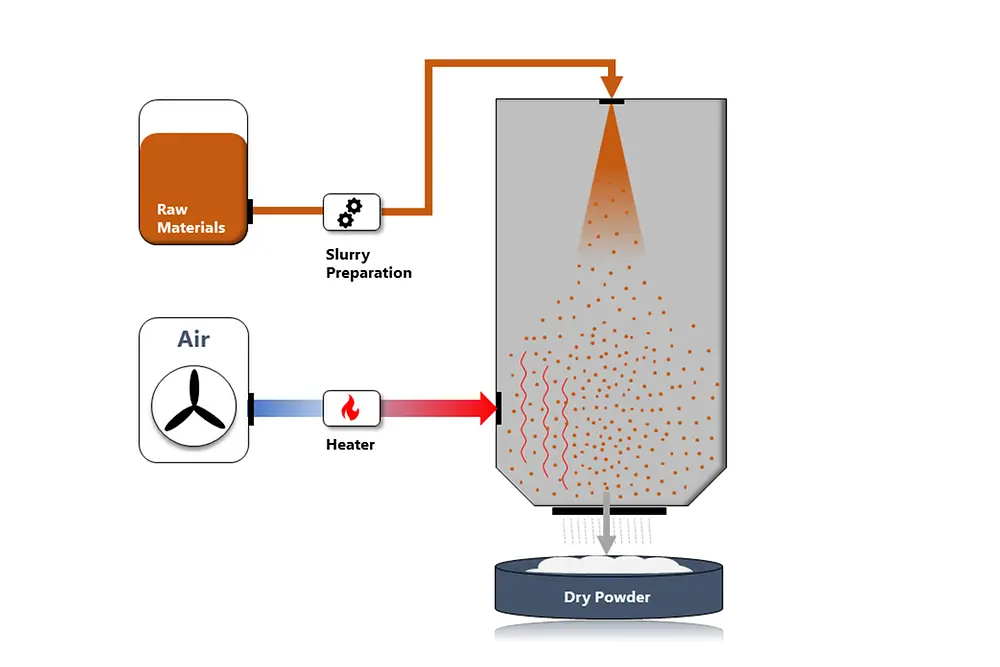

Optimizing processes in Düsseldorf, Germany

We also take action to save energy at long-established sites like our headquarters in Düsseldorf, Germany. In 2019, for example, we optimized our spraydrying tower at this site. This tower is used to make a powder that forms the basis for many of our laundry detergents – and more than one third of the energy consumed by our Laundry & Home Care business in Düsseldorf is used in this process. Our team installed additional sensors inside and outside the tower to gather more data, and this data is made available in our global Digital Backbone system. It enables us to increase the efficiency of our processes and to make comparisons across our sites worldwide. Following this successful pilot project in Düsseldorf, we’re implementing this data-driven approach across all of our factories that produce washing powder with spraydrying towers. This will empower our teams to identify opportunities to further increase energy efficiency by analyzing data at their site, as well as by benchmarking against other sites around the globe.

Implementing energy-saving measures in Bogotá, Colombia

Our optimized spraytowers are just one example of how we’re constantly implementing energy-saving measures in our production processes. Our Beauty Care team is also taking several steps to increase energy efficiency at our factory in Bogotá, Colombia. We’ve cut energy consumption for lighting by 5 percent by switching the entire site to LED bulbs. On top of this, we’re introducing a closed-loop pipeline system for carrying heated water that is used to make hair and body care products, which has the potential to cut emissions by 33 tons per year. And we’re also planning to install solar panels across the site’s 8,000-square-meter roof, while using digital technologies to drive continuous improvement and further increase our Overall Equipment Effectiveness.